Eco-materials

An unavoidable change

Our Matériauthèque will give you peace of mind.

Thanks to our eco-design and eco-material creation services, you can :

- Benefit from tested and certified eco-materials.

- Recycle your production offcuts in a closed circuit.

- Endlessly recycle your creations and production.

- Laboratory-test the performance of your eco-materials.

- Create new materials based on your production off-cuts.

- Enhance the value of your region’s production offcuts in a short circuit.

- Create new materials in small quantities.

- Control the traceability of your production off-cuts.

- Measure significant reductions in environmental impact.

Solar stainless steel

Product features:

Material: 100% recycled stainless steel in a short circuit and produced by a concentrated solar furnace specially developed for this type of product.

Environmental impact: 0.041 kg CO2-eq or 165 times less than conventional steel 6.8 kg CO2-eq.

Applications: mainly used for the manufacture of parts that will be in prolonged contact with the skin (anti-allergenic), for medical applications (bio-compatibility) and especially for its aesthetic qualities which guarantee a perfect polish (hyper regulated molecular mesh).

Batch certificate: guarantee of traceability of raw materials used.

Available formats:

- Bar stock: diameters of 16mm, 45mm, 60mm, length 3 meters.

- Flat stock: 65mm x 10mm x 1000mm or 62mm x 6mm x 1000mm.

- To order: by 1.000kg according to your custom dimensions.

Process specifications: hot rolled bar, descaled, Hyper hardened, ground h9 for round and hex stock, sandblasted for the flat.

Designation: AISI 316L, DIN 1.4441 ; X2CrNiMo18-15-3.

Recycled stainless steel

Product features:

Material: 100% short circuit recycling of stainless steel specially developed for this type of product.

Environmental impact: 0.63kg CO2-eq or 10 times less than conventional steel 6.8 kg CO2-eq

Applications: mainly used for the manufacture of parts that will be in prolonged contact with the skin (anti-allergenic), for medical applications (bio-compatibility) and especially for its aesthetic qualities which guarantee a perfect polish (hyper regulated molecular mesh)

Batch certificate: guarantee of traceability of raw materials used.

Available formats:

- Bar stock: diameter 16mm, 45mm, 60mm, length 3 meters.

- Flat stock: 65mm x 10mm x 1000mm or 62mm x 6mm x 1000mm

- To order: by 1.000kg according to your custom dimensions

Process specifications: hot rolled bar, descaled, Hyper hardened, ground h9 for round and hex, sandblasted for the flat.

Designation: AISI 316L, DIN 1.4441; X2CrNiMo18-15-3.

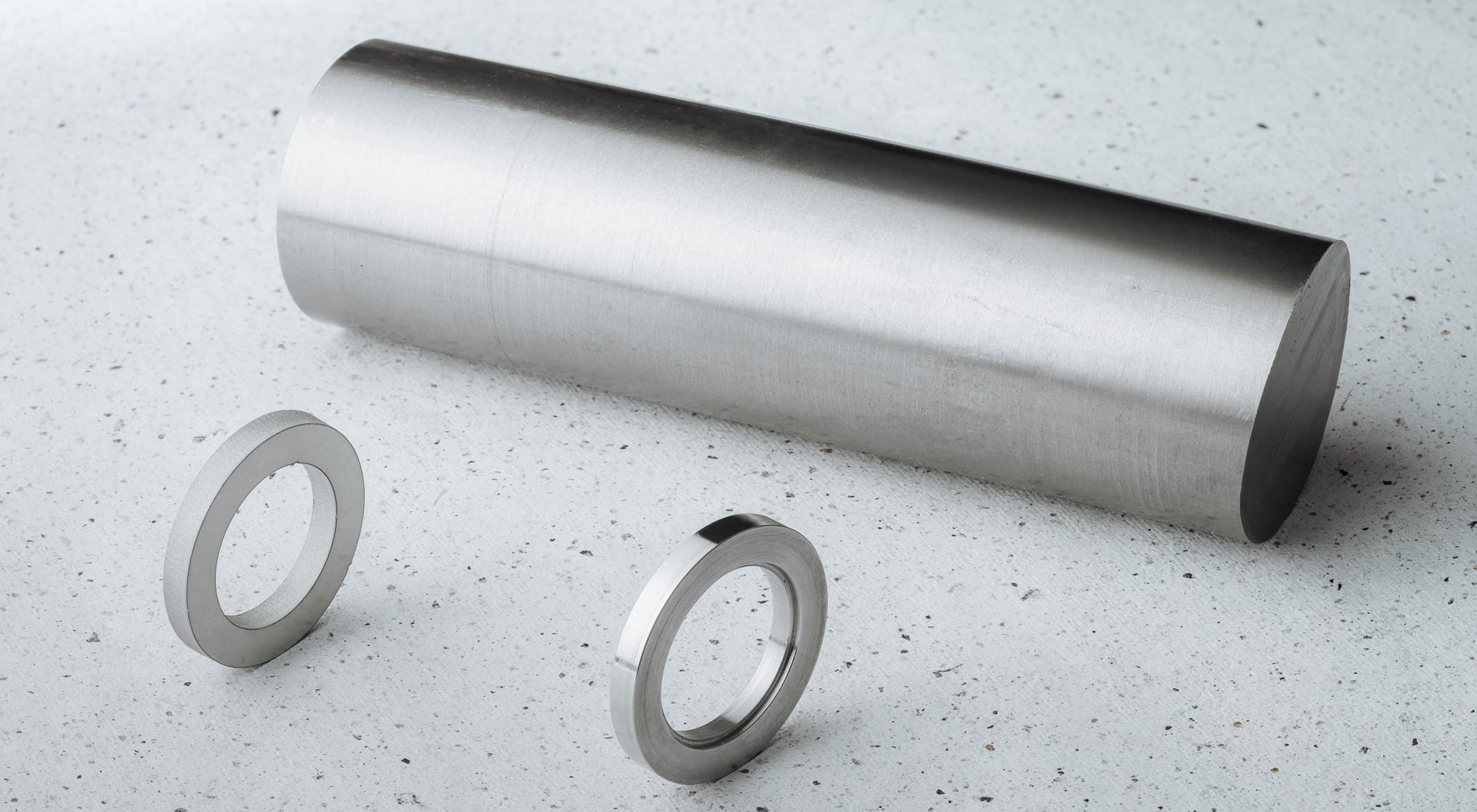

100% recycled titanium

Product features:

Material: 100% short circuit recycled titanium.

Environmental impact: very large reduction, not measured.

Applications: mainly used for its low density, extremely low weight and high resistant to shocks and especially for its perfect aesthetics (hyper regulated molecular mesh). It can be in prolonged contact with the skin (anti-allergenic).

Batch certificate: guarantee of traceability of raw materials used.

Available formats:

- Bar stock: diameter of 45mm, 48mm, 60mm, length 0.80 to 1.20 meter.

- To order: by 200 kg according to your dimensions.

Process specifications: forged bar, heat treated, ground h11 and cut to length.

Designation: DIN 3.7165, Grade 5, Ti6A14V.

ZEP 1510 ®

Product features:

Material: Alloy recycled by electrolysis from waste ash from the Kebag incineration plant in Zuchwil and drawn by the Grillo company in Duisburg.

Environmental impact: 0.30 kg CO2-eq or 10 times less than a conventional copper alloy 3 kg CO2-eq.

Applications: mainly used for the manufacture of fittings and decorative parts, this alloy replaces brass or nickel silver. It complies with the new European legislation on lead-free alloys while guaranteeing the same high level of machining and aesthetic performance, such as guilloché, shot peening and beading.

Batch certificate: guarantee of traceability of raw materials used.

Available formats:

- In strips: extruded from 0.3 to 2 mm and drawn from 7 to 20 mm, in rolls.

- Round bar stock : diameters 8 to 50 mm, length 300 mm to 3.000 mm.

- Flat stock, profiles, tubes: inscribed in a circumference of 50 mm, small quantities possible.

- To order: 500 kg according to your dimensions.

Process specifications:

- Bar: cast in bloom /billet, hot extruded, drawn, finished tolerance h9 or +/- 0.1, length setting.

Strips: cast in strip, rolled, finished tolerances +/- 0.1.

Designation: ZnAI15Cu1MG.

Comment:

“In 2022, Panatere offered the International Watchmaking Museum of La Chaux-de-Fonds its first ingot of recycled and solar-powered steel. A milestone that will leave a lasting mark on more than five centuries of watchmaking history.“

Régis Huguenin-Dumittan

La Chaux-de-Fonds MIH curator