They are talking about us!

Headlines, small inserts, reports, news in TV-news, radio interviews, local or international press, generalist or specialized magazines, the media and journalists closely follow our innovations.

Here are some ofthe most interesting references.

The heat is on for waste!

A solar furnace will soon be lighting up La Chaux-de-Fonds. It will enable waste from the metallurgical industry to be reused thanks to the sun. The first solar ingot should see the light of day in the next few weeks.

Swiss Ethics Award 2024

On Tuesday May 28, four prizes were awarded at the Swiss Ethics Award 2024 ceremony. The prize is awarded to Swiss companies and organizations committed to social responsibility or sustainable development projects.

Recycled Steel in Watchmaking: A Minimal Impact?

The world of watchmaking is increasingly embracing recycled steel. But what does "recycling" really mean, and what is its true impact on the planet? Let's take a closer look at this complex issue, especially in the context of watchmakers.

They turn our waste into gold

Is waste tomorrow's resource? According to the circular economy model, it certainly is. Several companies in Western Switzerland are already making their mark in this new branch of industry, which will have us rethinking our relationship with matter.

Chopard Forges Ahead With 80 Percent Recycled Steel for All Watches

It will be high time for recycled steel, as Chopard revealed Monday there would be a minimum of 80 percent of its proprietary Lucent Steel in its watches by the end of 2023. By 2025, the target is 90 percent.

Panatere combines industry and sustainability

Thanks to its metal remelting process, the Jura-based watchmaking subcontractor is transforming the way in which metallurgical waste is treated. It is also investing in a solar furnace and continuing its development of recyclable eco-materials.

Iris Alt: combining femininity and ecological awareness

It is clear that on the current market, the options for so-called "feminine" watches remain quite limited. A designer with a passion for jewelry watches intends to change this, while favoring the most eco-responsible design possible.

Responsible production of 100% recycled and recyclable materials

Panatere, a Swiss raw materials processing company, recognized in the watchmaking and medical industries, is the first player in its sector to offer sustainable raw materials.

Opposition delays the installation of the first industrial solar oven in La Chaux-de-Fonds

Panatere was supposed to start up the first industrial solar furnace for the production of recycled steel in La Chaux-de-Fonds on Tuesday 27 September. Opposition has delayed the launch of this project, but does not affect the motivation of the founder of the company based in the Jura.

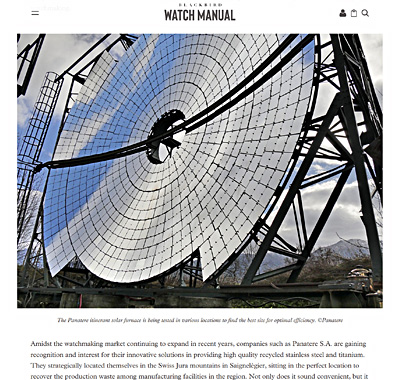

Panatere at the origin of the first solar furnace for metal processing

The Saignelégier company Panatere, a pioneer in the transformation of 100% recycled and recyclable raw materials recognized in the watchmaking and medical worlds, is the originator of the first concentrated solar furnace for the treatment of metals for microtechnology. A factory incorporating this technology will soon be built in La Chaux-de-Fonds.

We have gone from watchmaking subcontractors to Jura alchemists.

Starting from a desire to improve the quality of its raw material, the Jura family SME Panatere has changed in size. From watch industry subcontractor to international reference for solar oven technologies, the story of a metamorphosis.

Musings: Deciphering Sustainability

Amidst the watchmaking market continuing to expand in recent years, companies such as Panatere S.A. are gaining recognition and interest for their innovative solutions in providing high quality recycled stainless steel and titanium.

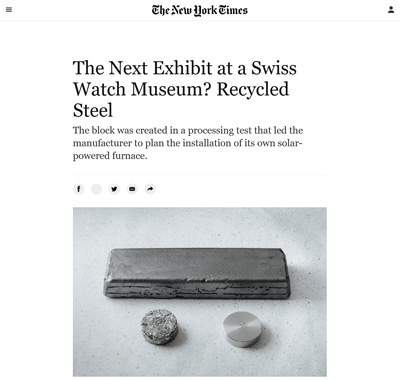

The first 100% recycled and solar-powered stainless steel ingot exhibited at the MIH

Among the new acquisitions of the International Watch Museum, in La Chaux-de-Fonds, there is the first steel ingot recycled in a solar oven, from the Panatere company.

Is solar steel the future of watchmaking?

The solar oven that Panatere is building in the Watch Walley will be capable of producing tons of steel.

Panatère, Leader in the recycling of stainless steel and titanium

1500 tons of 16L stainless steel goes to waste in the manufacturing process of the various parts for watchmaking. Is it really reasonable that this very good quality steel should no longer be reused in the watch industry? The Panatere company in Saignelégier offers a circular economy solution.

Panatere rewarded at the Luxury Innovation Summit.

Organized by the Luxury Venture, this summit attracted participants from more than 12 countries - from startups to established brands and Heritage Houses. Six winners of the Luxury Innovation Awards 2021 were awarded among 71 applications. The Panatere Group won a prize in the “Responsibility & Sustainable Development” category.

The Next Exhibit at a Swiss Watch Museum? Recycled Steel

This month a block of steel is to be added to the collections of the Musée International d’Horlogerie, an institution operated by the watchmaking city of La Chaux-de-Fonds, in what Switzerland’s tourist authorities call Watch Valley. To the untrained eye, the block could pass for a minimalist sculpture, an archaeological find or a polished meteorite mysteriously fallen to Earth.

A solar steel

This stainless steel is 100% produced from metal waste from local components production of watch and medical industries. This short-circuit harvesting process, followed by a rigorous sorting of the scraps then by a recasting of the material thanks to an industrial solar furnace makes it possible to drastically reduce the CO2 emissions necessary for the manufacture of steel.

Panatere: first steel, now recycled titanium.

From early 2022, Panatere will be ready to supply the watch industry with recycled titanium produced using waste recovered from companies in the Swiss Jura, through a system initially set up for recycling steel. The company is also working on an itinerant solar furnace.

Solar oven and short circuits

What if, after the era of influencers, sated with followers and egocentrically dazed by their navels, a new species was born, the “possibilists”? It was Raphaël Broye, owner and director of Panatere, who suggested this neologism to me. A utopian? Rather a visionary...

A treasure was behind my factory!

After a first life as a “disruptive entrepreneur”, Raphaël Broye founded the company Panatere in Saignelégier in 2012, which recycles stainless steel for the Swiss watch industry. Convinced that recycling is a wealth for the industrial future of our region, he will share with us his vision of a “Swiss Made” circular economy and his regional solar foundry project.

The nobility of waste

Today, environmental awareness is pushing for less futile recycling. According to the specifications that the owner and director of Panatere has set himself, we go further than just the watch case. "We worked on each component and the bracelets were part of our overall vision"...

Sustainability, skills for the future

When Raphaël Broye, head of Panatere, drew up his roadmap for the installation of a solar oven in the Jura, when he embarked on the production of recycled steel, he found in Reconvilier a sizeable ally.

Panatere is committed to the production of 100% recycled and recyclable steel

PANATERE, a member of Circular Economy Switzerland, is located in Saignelégier in Switzerland. It is a pioneer in the transformation of 100% recycled and recyclable raw materials.

The circular economy is on the move

Luxury watchmaking and jewelery is in turn embarking on the sustainable economy. Cartier, Gucci and Yves St Laurent are committed to reducing their impact on the environment. A small Geneva brand did not wait, it manufactures watches with steel recovered from the recycling center...

EPHJ 2021 - Exhibitors Innovation Grand Prix

In today's report, we go back to the EPHJ, the high precision trade fair that was held in Geneva a couple of weeks ago and especially on the Grand Prix the trade show organises for each edition rewarding innovation. Panatere was nominated for their innovation which consists in producing solar steel using a solar furnace and scrap from the production of watch and medical components and by doing so having steel which has a 0 carbon impact.

Swiss watchmaking industry embraces the circular economy

Powering through some 120,000 tonnes of stainless steel per year, Switzerland’s industry is one of Europe’s hungriest consumers of the metal. As the industry comes under increased pressure to reduce its environmental impact, local entrepreneurs are moving to establish recycling chains to enable this valuable raw material to be reused including in the watchmaking industry.

Discover the best inventions of the region presented in Geneva

Last week, manufacturers from the Jura Arc emerged from a period without a show of almost two years to present their new products to visitors to the EPHJ in Geneva. In Saignelégier, Panatere produces watchmaking quality steel by recycling shavings from local micromechanical production.

Solar steel from the Jura?

Heavy at Panatere, yes, but heavy zero carbon! Joining the action to the word, such was the approach rather well perceived by this SME already well anchored for 10 years in the landscape of watchmaking-jewelry and related sectors, other microtechnology in particular.

Swiss Made circular, the ultimate luxury.

Chips, the black gold of the Jura. One day soon, not so far away in fact, waste will become raw material. And therefore, no longer at the origin of costs related to their displacement and their destruction, but of the kilos to monetize. Already, when Panatere, a Jura SME, undertook to federate...

Kari Voutilainen at the pinnacle

Finnish master watchmaker Kari Voutilainen has come a very long way from southern Lapland, where he was born and raised, to the vertiginous eyrie known as Le Chapeau de Napoléon (Napoleon’s Hat) where he has recently installed…

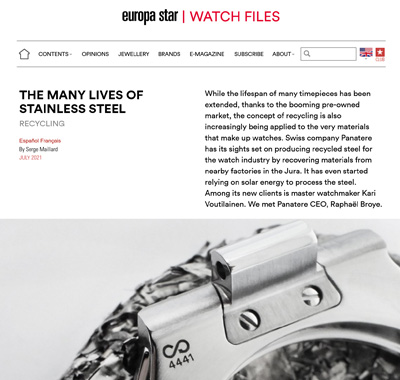

The many lives of stainless steel

While the lifespan of many timepieces has been extended, thanks to the booming pre-owned market, the concept of recycling is also increasingly being applied to the very materials that make up watches. Swiss company Panatere has its sights set on producing recycled steel for the watch industry by recovering materials...

Panatere as an actor of sustainability

Panatere, a major player in the watch and medical industries, has become the first in its sector to offer sustainable raw materials. Following on from its fully recycled and recyclable stainless steel, the Jura-based SME has just taken delivery of its first “solar” steel melts.

Recycled steel thanks to solar power for watchmaking

Following its offer of 100% recycled and recyclable stainless steel, the Jura-based SME Panatere receives its first castings of “solar” steel. For the very first time in Switzerland, the study of a regional solar oven located in the Watch Valley is studied…

Zero waste watches made in the Jura

In this watchmaking company, we recently imagined the country's first recycled stainless steel sector. An unprecedented approach which follows an observation: the quality of steel imported from abroad is not always satisfactory.

When watches hide to die.

Behind the walls of the Reconvilier waste disposal center in the Bernese Jura, hundreds of thousands of items are destroyed each year. Their materials are recycled, as are the steel shavings from machining, to supply brands that focus on the circular economy.

PANATARE introduces a fully recycled and recyclable steel…

PANATERE, a Swiss company specialising in the transformation of raw materials and a major player in the watch industry, has become the first in its sector to offer sustainable raw materials. Following on from its fully recycled and recyclable stainless steel, the Jura-based SME has...

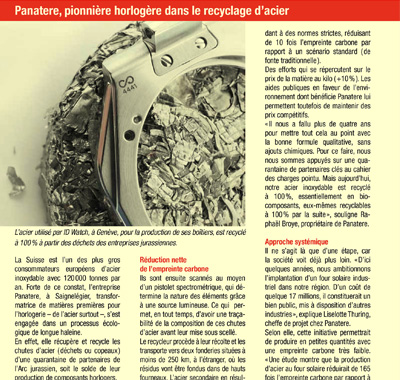

PANATARE SA, the first watch in recycled steel!

Switzerland is one of the largest European consumers of stainless steel with 120,000 tonnes per year. On the strength of this observation, the Panatere company, in Saignelégier, a processor of raw materials for watchmaking – especially steel – has embarked on a long-term ecological process.

They recycle Jura steel…

In Saignelégier (JU), watchmaking subcontractor Panatere collects and recycles steel scrap from factories in the region. For the bracelets, an ecological leather made from apples, fennel and grapes has been developed.

The dream of zero-waste watchmaking.

An industrialist from Saignelégier has set up a recycled stainless steel industry. Alongside it, 40 companies in the region are involved in cleaner metallurgy. With the dream of doing even better: melting steel without fossil fuels or electricity.

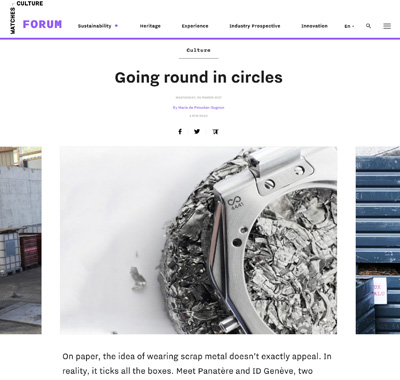

A 100% recycled steel watch

Two companies from Jura and Geneva are joining forces and ideals to offer a first watch in recycled steel. Their objective is to recover waste to produce a luxury product, while preserving natural resources.

PANATERE, pioneer in the production of 100% recycled and recyclable stainless steel

PANATERE, a Swiss raw materials processing company, recognized in the watch industry, becomes the first player in its sector to commit to “Circular Economy Switzerland”. Focusing on a sustainable solution, its production of 100% recycled and recyclable stainless steel...

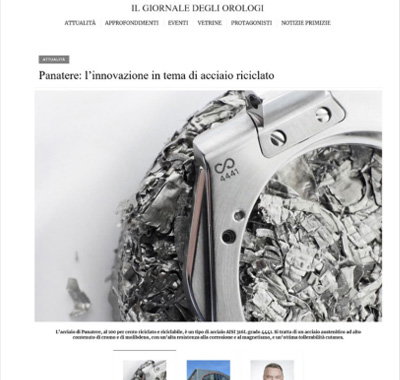

Panatere: innovation in recycled steel

Panatere produces durable watch cases. The main activity of the company is the recovery and transformation of raw materials such as steel, titanium, gold and platinum. According to its press release, Panatere is now the first company in the sector to join the "Circular Economy Switzerland" association.

Panatere - A pioneering commitment to…

Panatere, a Swiss company specialising in the transformation of raw materials and a major player in the watch industry, has become the first in its sector to be involved with "Circular Economy Switzerland. Geared towards a sustainable solution, the company's products, wich are made...

Panatere joins Circular Economy Switzerland

Panatere produces durable watch cases. The main focus of the company is the recovery and transformation of raw materials such as steel, titanium, gold and platinum. According to its press release, Panatere is now the first company in the sector to join the "Circular Economy Switzerland" association.